Reduce vibrations and improve refinement with modern engine mounts for the four-cylinder engine

After forty or fifty years under constant compression, the integrity of the rubber in the engine mounts of a four-cylinder P6 engine will undoubtedly have deteriorated. In an effort to return your four-cylinder to original levels of noise, vibration and hardness (NVH), you might consider replacing the engine mounts. But with used examples offering slim to no improvement, and unused original stock parts practically unobtainable, it makes good sense to source similar mounts from a modern car and modify them to fit. Not only will these parts be readily and cheaply available, they will also offer more modern standards of NVH reduction through the use of more advanced rubber compounds than were available in the early 1960s.

After forty or fifty years under constant compression, the integrity of the rubber in the engine mounts of a four-cylinder P6 engine will undoubtedly have deteriorated. In an effort to return your four-cylinder to original levels of noise, vibration and hardness (NVH), you might consider replacing the engine mounts. But with used examples offering slim to no improvement, and unused original stock parts practically unobtainable, it makes good sense to source similar mounts from a modern car and modify them to fit. Not only will these parts be readily and cheaply available, they will also offer more modern standards of NVH reduction through the use of more advanced rubber compounds than were available in the early 1960s.

As it happens, the rear left gearbox support mount from a Mk3 VW Golf/Jetta is a perfect fit for a four-cylinder P6, requiring the smallest level of modification to fit and offering substantially improved engine isolation.

All credit for this discovery goes to Demetris Bouras of Thessaloniki, Greece, whose White German-export specification Series 1 2000 TC is a regular sight on the Classic Rover Forum, where this excellent modification was first posted.

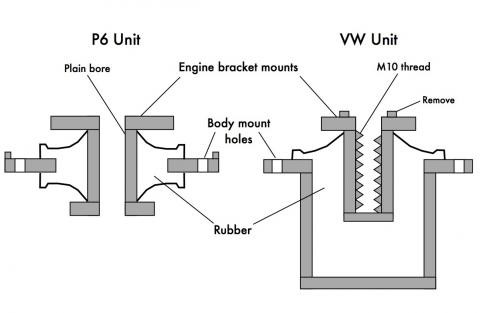

In the picture above is a comparison of the original Rover 2000 engine mounts and the VW units. By sheer luck and a happy crossover of imperial and metric measurements, the locating holes are in exactly the same place as the P6 unit, so the new mounts can in theory be dropped straight in situ.

The only significant difference is the outside diameter of the cup beneath the VW mount. This is 80mm, where the hole in the base is 3 ½ inches – a difference of just over 1mm, or about 40 thou. The thickness of the paint makes up some of this, but to ensure a perfect fit you need to use a half-round file and grind away around half a millimetre from the inside lip of the hole in the base unit, creating a 1mm increase in inside diameter. With this removed, the mount drops neatly into place and can even be secured with the original bolts. It is a good idea to grind away enough material to leave a decent wiggle room to aid when lining the engine up later.

Mounting the ‘crows foot’ engine bracket to the new mount is equally straightforward. The only modification required is the filing flat of the two locating tabs on the top face of the mounts to allow the faces to mate flush. An 80mm M10 bolt chopped down to 65mm is the perfect length to ensure the maximum thread area of the mount is used without the bolt touching down.

The mounts can be installed with the engine in situ. Begin by extracting the long bolts securing the engine brackets to the original mounts, remove the engine tie rod at the front of the engine, and disconnect the exhaust pipe (from the manifold on SC’s and at the first joint in the main pipe for TC’s). Jack the engine securely from underneath until it lifts off its present mountings. Remove the ‘crows feet’ engine brackets from the sides of the engine to gain a good working space around the mount holes for filing. It is straightforward to remove the right hand bracket (on the distributor side) to allow good access to the hole in the base unit. On the left side, you will to remove the carburettor as a minimum, and TC owners should remove carburettors and inlet manifold as a single assembly. The exhaust manifold can be left in situ but is advantageous to remove it at this point. If you do leave it in place, be wary of movement and stress on TC pipes.

With the holes in the base unit filed away, the mounts can drop in place. Put the securing bolts loosely in place and bolt the bracket to the mount with a few turns of the M10 bolt. Do this on both sides to ensure everything is located properly before lowering the engine onto the mounts and tightening up all of the fixings.

With everything now sitting in place nicely, you need to slide under the car and take a look at the rear gearbox mount. The snub rubber should be sitting exactly in the middle of the support bar, with the spring underneath perfectly perpendicular to the road. If the gearbox is misaligned, excessive transmission noise and juddering at takeaway can occur (often misdiagnosed as clutch judder, this is actually the whole misaligned drivetrain jumping!). Once in place, you can reattach the front engine tie bar and tighten it until the rubber bushes are just under compression, but not squeezed tight – a remarkable amount of vibration can be transmitted through this bar alone, so ensure it is not over-tight. If in doubt, replace the bushes, either by sourcing replacements or carving by a soft and pliable bush material roughly to shape – these are far from precision bushes.

With all of that completed, you should now be able to enjoy original levels of refinement and engine isolation in your 2000 or 2200.

These new mounts can be bought new as “VW Golf/Jetta Mk3 rear left engine mount” from most motor factors, or from eBay by searching for “vw golf mk3 left rear engine mount” for as little as £12 each including delivery.

Should I be concerned?

Replacing any original stock part with a modern alternative is always fraught with worries and can spark fierce debate. However, with two committee members having been using these mounts for at least 2 years, we are satisfied that this modification offers substantial positive benefit with no discernible drawbacks. Vibration at idle is dramatically reduced, and the engine feels much smoother and more distant at motorway speeds.

The rubber compound in the VW mounts is much softer and more pliable than the originals, and clearly works well in a P6 application. The height of the engine remains virtually the same as original (once the new rubber is compressed in situ), and given that these mounts were designed to work alone, supporting one end of a diesel drivetrain, we have no real concerns about collapsing or compromised longevity.

This diagram below shows the sectional view of the mounts. The substantially larger rubber volume can clearly be seen in the VW unit. The P6 unit is in effect a steel ‘cotton reel’ suspended in a rubber ‘doughnut’. The VW unit is a threaded pipe centred in deep well, backfilled with a modern rubber compound.

Words: Michael Allen

Originally published in Driving Force magazine

August 2013